The Glass Fiber Rod Molds from Huiseng Machinery are essential customized equipment designed for the high-precision molding of glass fiber rods in industries such as photovoltaic (PV) and outdoor products. These molds ensure the dimensional accuracy, surface texture, and mechanical properties of glass fiber rods, catering to the production needs of rods with different diameters (3-50mm), including PV bracket rods, tent load-bearing rods, and insulating glass fiber rods.

✅ Why Choose Huiseng’s Glass Fiber Rod Molds?

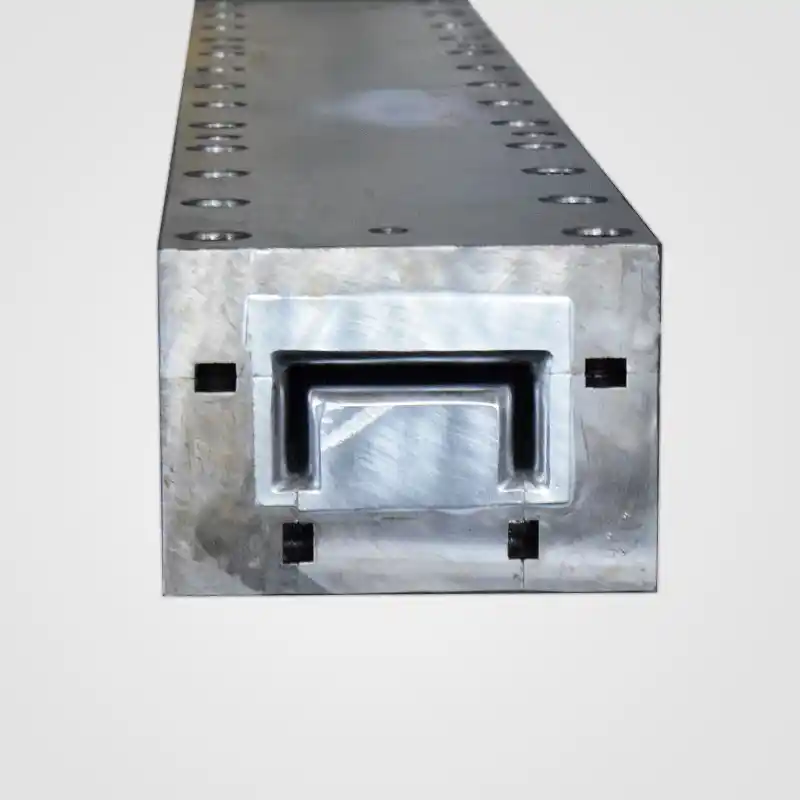

🔹 Precision Molding with High-Strength Alloy Materials

- Made from high-strength materials like aluminum alloy and mold steel, ensuring durability and reliability

- Inner walls are precision-polished to a surface finish of ≤ Ra0.8μm, minimizing pockmarks or scratches on the molded rods

- Dimensional errors are controlled within ±0.2mm, meeting stringent requirements for installation accuracy in the PV industry and aesthetic standards for outdoor products

🔹 Anti-Stick Coating for Smooth Demolding

- Pre-coated inner walls with high-temperature resistant and anti-stick coatings

- Can withstand common molding temperatures of 120-180°C, ensuring fast and non-destructive demolding

- Reduces damage to rod surfaces during demolding and minimizes the need for frequent mold cleaning

🔹 Customizable Design for All Scenarios

- Support customization in terms of rod length (from 1m to 10m+), cross-sectional shape (circular or special-shaped), and special structures (e.g., reserved connection holes)

- Adapt to the load-bearing structure of PV bracket rods and the lightweight design of outdoor tent poles

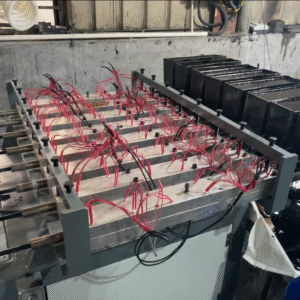

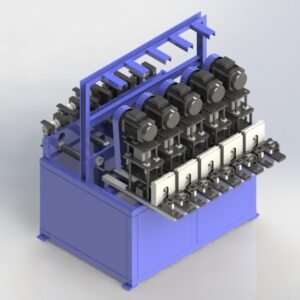

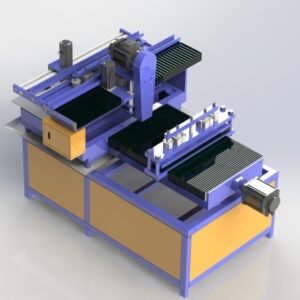

- Accurate matching interfaces with glass fiber rod molding machines and traction machines ensure a seamless production process

🔹 Extended Service Life and Cost Efficiency

- Capable of continuous production of more than 100,000 rods under normal working conditions

- Reduced frequency of mold cleaning and extended service life contribute to cost efficiency and stable product quality

🛠️ Technical Specifications

| Parameter | Specification |

|---|---|

| Applicable Rod Diameter | 3 mm – 50 mm |

| Dimensional Accuracy | ±0.2 mm |

| Surface Finish | ≤ Ra0.8 μm |

| Material | Aluminum Alloy / Mold Steel |

| Coating Type | High-Temperature Resistant & Anti-Stick Coating |

| Temperature Range | 120°C – 180°C |

| Length Range | 1 m – 10 m+ (customizable) |

| Cross-Sectional Shape | Circular, Special-Shaped (customizable) |

| Special Structures | Reserved Connection Holes (optional) |

🌍 Applications Across Industries

- Photovoltaic (PV): Mounting brackets, solar racking support rods

- Outdoor & Camping: Tent poles, canopy frames, hiking gear components

- Electrical: Insulating rods for high-voltage applications

- Construction: Lightweight composite structural elements