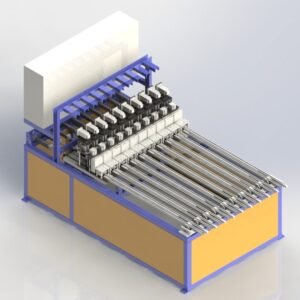

Multi-Station Cutting Machine for Glass Fiber Rods

The Multi-Station Cutting Machine is a high-performance, fully automated solution designed specifically for the precise and efficient cutting of glass fiber rods in the photovoltaic (PV) and outdoor product industries. This advanced equipment seamlessly integrates with glass fiber rod molding and traction machines, replacing traditional manual cutting methods that suffer from low precision, inefficiency, and frequent rod damage.

✅ Key Features & Advantages

🔹 PLC Intelligent Control System

- Supports preset cutting lengths with an accuracy of ≤±0.5mm

- Enables both single-rod and continuous batch cutting without recalibration

- Ideal for mass production of fixed-length PV bracket rods and multi-size tent load-bearing rods

🔹 Multi-Station Design for High Throughput

- Multiple cutting stations operate simultaneously, significantly increasing output

- Reduces idle time and improves overall production efficiency by over 300% compared to manual operations

🔹 Anti-Offset Clamping Mechanism

- Firmly holds the rod during cutting to prevent breakage, burrs, and deformation

- Ensures clean, smooth cuts even on large-diameter rods (up to 50mm)

🔹 High-Speed, Wear-Resistant Cutting Tools

- Interchangeable blades to meet varying strength requirements for insulating rods vs. structural load-bearing rods

- Durable design reduces maintenance frequency and downtime

🔹 Safety & Real-Time Monitoring

- Equipped with infrared protection sensors and emergency stop buttons for operator safety

- Built-in counter tracks the number of cut rods in real time, enabling accurate production data collection and management

🔹 Compact & Flexible Integration

- Compact footprint allows easy integration into existing glass fiber rod production lines

- Suitable for both small-scale workshops and large-scale industrial factories

🛠️ Technical Specifications

| Parameter | Specification |

|---|---|

| Applicable Rod Diameter | 3mm – 50mm |

| Cutting Accuracy | ≤±0.5mm |

| Cutting Speed | Adjustable (up to 200 pcs/min) |

| Power Supply | 380V / 50Hz (customizable) |

| Control System | PLC + Touch Screen Interface |

| Dimensions | 1200 × 800 × 1500 mm (approx.) |

| Weight | ~450 kg |

| Output | Up to 6 cutting stations (configurable) |

🏭 Applications

✔️ Photovoltaic Industry: PV mounting bracket rods, solar panel support rods

✔️ Outdoor Products: Tent poles, canopy frames, camping gear components

✔️ Electrical Insulation: High-voltage insulating rods

✔️ Industrial Equipment: Composite structural parts

✅ Why Choose Our Multi-Station Cutting Machine?

- ✔️ Factory Direct Pricing – No middleman markup

- ✔️ Customizable Configurations – Adjust station count, power, and control interface as needed

- ✔️ Full After-Sales Support – Technical training, spare parts supply, remote troubleshooting

- ✔️ CE Certified – Meets international safety and quality standards