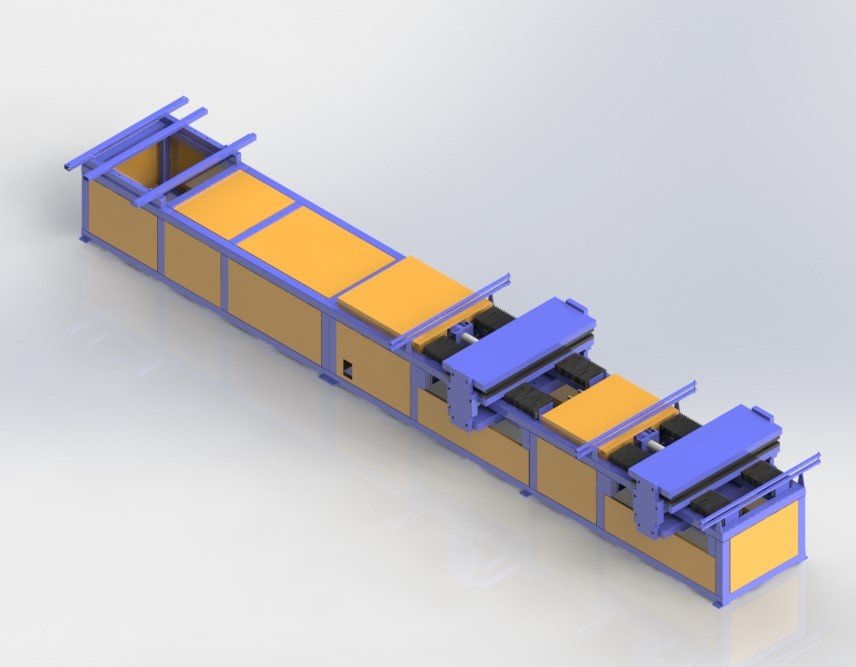

In terms of core performance adapting to industry scenarios: the machine adopts a “high-tonnage hydraulic power + multi-group anti-slip traction wheel” design. The 10-ton traction capacity can stably pull PV bracket glass fiber rods (mostly large-diameter and high-rigidity), avoiding production interruptions caused by traction stagnation. The 15-ton clamping capacity can firmly fix the rods, preventing the deviation of PV rods during traction and the rotation of glass fiber rods for outdoor products (such as tent load-bearing rods and awning support rods) during traction. At the same time, the hydraulic system enables precise pressure control, eliminating rod surface damage caused by excessive clamping force. The traction wheels are made of high-wear-resistant elastic materials, which fit the insulation and folding-resistant properties of glass fiber rods, ensuring that PV rods have no tensile deformation (guaranteeing installation accuracy) and outdoor product rods have no surface scratches (improving product aesthetics), thus adapting to the production of multi-specification glass fiber rods in the two industries.

In terms of configuration optimized for industry production needs: the machine is equipped with an intelligent speed control panel, which can real-time monitor traction force, clamping pressure and operating speed, adapting to the large-scale mass production rhythm of the PV industry and the multi-batch model change needs of the outdoor product industry, and is easy to operate. An emergency stop button is added to quickly shut down the machine in case of abnormalities, reducing the loss risk in the high-value production of PV rods. The machine body is made of lightweight steel structure, occupying a small floor space, and can be flexibly connected to glass fiber rod molding machines and cutting machines. It can not only be integrated into the continuous production line of PV bracket rods, but also adapt to the multi-category production scenarios of glass fiber rods for outdoor products, greatly improving production efficiency and becoming a core supporting equipment for glass fiber rod production in the PV and outdoor product industries.