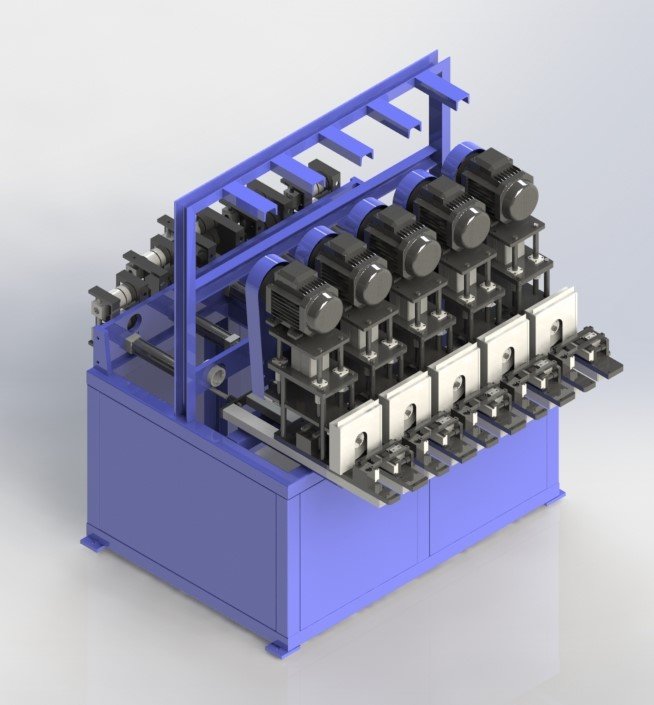

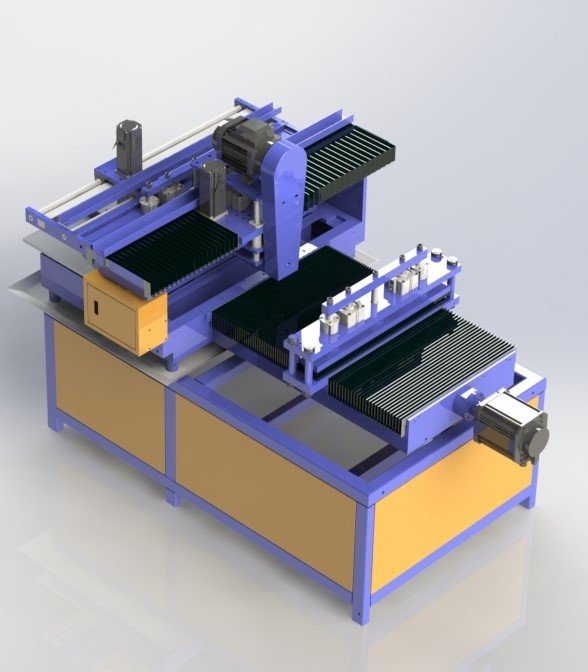

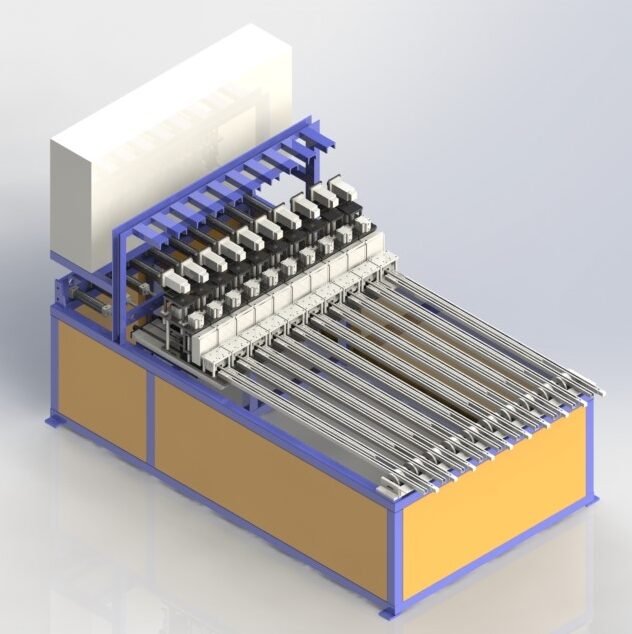

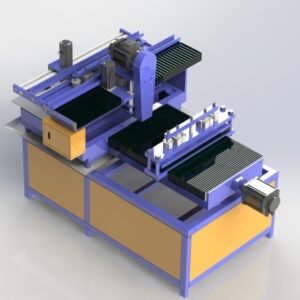

Automated Multi-Station Cutting Equipment-2 – Next-Gen Batch Processing Solution

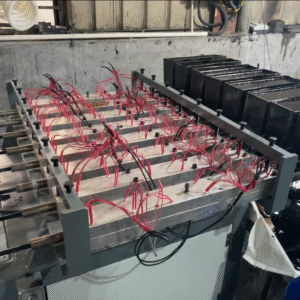

The Automated Multi-Station Cutting Equipment-2 from Huiseng Machinery is a state-of-the-art industrial solution designed for high-volume, high-precision cutting of glass fiber rods in the photovoltaic (PV), outdoor recreation, and composite manufacturing sectors. This advanced machine features multiple synchronized cutting stations, enabling continuous batch processing with minimal downtime—perfect for large-scale production lines.

✅ Why Choose Huiseng’s Multi-Station Cutter?

🔹 Unmatched Efficiency with Multiple Stations

- Up to 6 cutting stations operating simultaneously

- Dramatically increases throughput by over 300% compared to single-station or manual methods

- Ideal for producing thousands of uniform rods per hour

🔹 ±0.5mm Precision with PLC Control

- Fully programmable via touchscreen HMI

- Supports preset lengths without recalibration

- Ensures consistent quality for PV mounting brackets, tent poles, and insulating rods

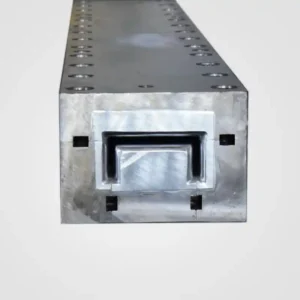

🔹 Smart Anti-Offset Clamping System

- Patented clamping mechanism prevents rod slippage during high-speed cutting

- Eliminates burrs, cracks, and deformation—even on brittle large-diameter rods (up to 50mm)

🔹 Interchangeable Tooling for Versatility

- High-speed, wear-resistant blades can be quickly replaced

- Compatible with both small-diameter insulating rods (3–10mm) and large-diameter load-bearing rods (10–50mm)

🔹 Real-Time Production Monitoring

- Built-in counter tracks number of cut rods in real time

- Enables accurate inventory management and production reporting

🔹 Safety & Reliability Designed In

- Infrared safety sensors automatically pause operation when hands approach

- Emergency stop button for instant shutdown

- CE-certified design meets international safety standards

🔹 Compact & Modular Design

- Minimal footprint allows easy integration into existing GFRP production lines

- Plug-and-play compatibility with molding and traction machines

- Easy maintenance and tool replacement

🛠️ Technical Specifications

| Parameter | Specification |

|---|---|

| Applicable Rod Diameter | 3 mm – 50 mm |

| Cutting Accuracy | ≤ ±0.5 mm |

| Max Output Speed | Up to 200 pieces/minute (adjustable) |

| Number of Stations | 6 (configurable) |

| Control System | PLC + 7″ Color Touchscreen |

| Power Supply | 380V / 50Hz (customizable for global markets) |

| Machine Dimensions | 1200 × 800 × 1500 mm (L×W×H) |

| Weight | Approx. 450 kg |

| Safety Certification | CE Compliant |

🌍 Applications Across Industries

- Photovoltaic (PV): Mounting brackets, solar racking support rods

- Outdoor & Camping: Tent poles, canopy frames, hiking gear components

- Electrical: Insulating rods for high-voltage applications

- Construction: Lightweight composite structural elements