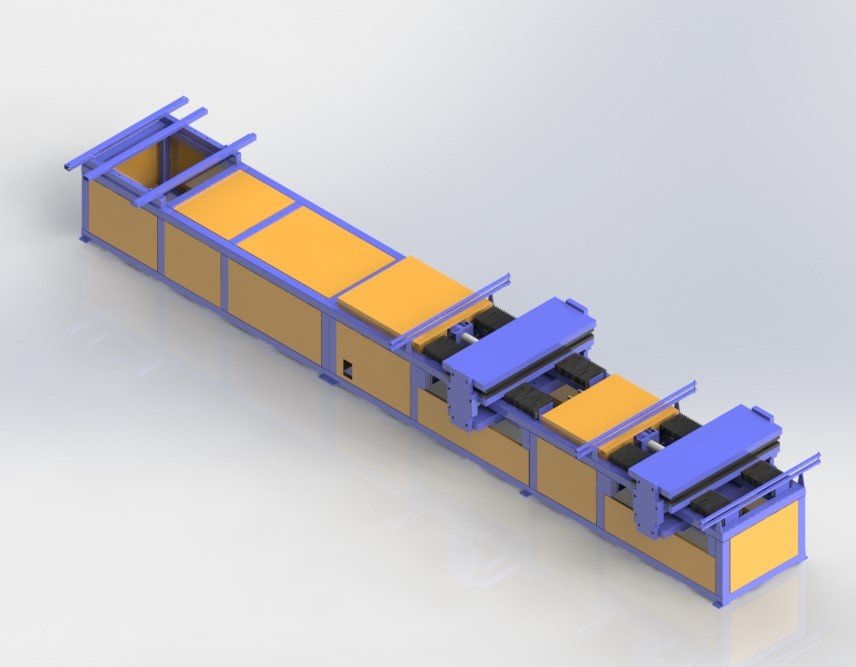

Hydraulic Pulling Machine for Glass Fiber Rods – Precision Traction Solution by Huiseng Machinery

The Hydraulic Pulling Machine for Glass Fiber Rods from Huiseng Machinery is a core component of modern composite rod production lines, specifically designed for the stable, high-force transportation and precise traction of glass fiber reinforced polymer (GFRP) rods after molding. This advanced equipment addresses common issues in traditional systems—such as insufficient pulling power, unstable clamping, and rod damage—by leveraging a high-tonnage hydraulic drive system and multi-stage anti-slip rollers, making it ideal for both photovoltaic (PV) and outdoor products industries.

✅ Why Choose Huiseng’s Hydraulic Pulling Machine?

🔹 Powerful Hydraulic Drive System

- 10-ton traction force: Ensures smooth and uninterrupted pulling of thick, rigid PV bracket rods (up to 50mm diameter)

- 15-ton clamping pressure: Firmly holds rods during motion, preventing slippage, rotation, or misalignment

- Precise hydraulic control adjusts pressure dynamically to avoid surface damage on delicate rods

🔹 Anti-Slip Roller Design with High-Wear Resistance

- Equipped with high-elasticity, non-marking rollers that conform to the shape of glass fiber rods

- Prevents scratches on outdoor tent poles and maintains insulation integrity on PV mounting rods

- Minimizes deformation and ensures dimensional accuracy throughout the production process

🔹 Smart Control Panel for Real-Time Monitoring

- Integrated digital interface allows real-time monitoring of:

- Traction force

- Clamping pressure

- Running speed

- Easily adapts to different production rhythms—ideal for mass production in PV industry and frequent mold changes in outdoor product manufacturing

🔹 Safety & Reliability Features

- Emergency stop button enables instant shutdown in case of anomalies

- Reduces risk of high-value PV rod damage during operation

- CE-compliant design meets international safety standards

🔹 Compact & Modular Structure

- Lightweight steel frame minimizes floor space usage

- Can be seamlessly integrated into existing glass fiber rod extrusion lines, molding machines, and cutting systems

- Suitable for both continuous PV bracket rod production and multi-specification outdoor pole manufacturing

🛠️ Technical Specifications

| Parameter | Specification |

|---|---|

| Applicable Rod Diameter | 3 mm – 50 mm |

| Traction Force | 10 tons |

| Clamping Pressure | 15 tons |

| Control System | PLC + Digital Display Panel |

| Power Supply | 380V / 50Hz (customizable) |

| Machine Length | Up to 12 meters (configurable) |

| Weight | Approx. 1,800 kg (varies by length) |

| Safety Certification | CE Compliant |